Welcome to the GMVC96 installation manual. This guide provides comprehensive instructions for installing the Goodman GMVC96 two-stage gas furnace, ensuring safe and proper setup. Follow the steps carefully to optimize performance and efficiency, while adhering to all safety guidelines and manufacturer recommendations.

1.1 Overview of the GMVC96 Furnace

The Goodman GMVC96 is a high-efficiency, two-stage gas furnace designed for reliable heating performance. With an AFUE rating of 96%, it offers superior energy efficiency and lower utility costs. This furnace operates on natural or propane gas, featuring a modulating burner and variable-speed blower for precise temperature control. Its two-stage heating ensures consistent warmth while reducing energy consumption. Compact and durable, the GMVC96 is ideal for various home sizes and climates. It is also compatible with smart thermostats, enhancing system control and efficiency. Built with advanced safety features, this furnace provides dependable and quiet operation, making it a popular choice for homeowners seeking long-term comfort and savings.

1.2 Purpose of the Installation Manual

This manual is designed to guide licensed professionals through the safe and proper installation of the Goodman GMVC96 gas furnace. It provides detailed instructions, safety precautions, and technical specifications to ensure a successful setup. The manual covers essential topics such as pre-installation checks, tools required, and step-by-step installation procedures. By following this guide, installers can ensure the furnace operates efficiently and safely, meeting all regulatory standards. It is crucial for users to read this manual thoroughly before starting the installation process to avoid potential hazards and ensure optimal performance of the furnace.

Safety Precautions

Adhering to safety guidelines is crucial during GMVC96 furnace installation. Always follow manufacturer instructions, wear protective gear, and ensure proper ventilation to avoid hazards and ensure a safe setup.

2.1 General Safety Guidelines

Always prioritize safety when installing the GMVC96 furnace. Thoroughly read the manual before starting. Ensure proper ventilation to prevent gas leaks. Turn off power and gas supply before beginning work. Wear protective gear, including gloves and safety goggles. Keep the installation area clear of flammable materials. Avoid overreaching or standing on unstable surfaces. Follow all local building codes and manufacturer instructions. Never attempt installation without proper training or tools. Failure to adhere to these guidelines can result in serious injury or system damage. Ensure all safety precautions are strictly followed to guarantee a safe and successful installation process.

2.2 Hazardous Conditions to Avoid

During GMVC96 furnace installation, avoid hazardous conditions that could lead to accidents or system damage. Never install the furnace in areas with flammable materials nearby. Ensure proper ventilation to prevent carbon monoxide buildup. Avoid exposing the furnace to direct water contact or high humidity. Gas leaks are a critical hazard; always check connections with a soap solution. Do not operate the furnace if there are signs of damage or malfunction. Keep the area free from obstructions to maintain airflow. Avoid overloading electrical circuits, as this can cause fires. Always follow proper shutdown procedures to prevent accidental startups. Addressing these hazards ensures a safer installation environment.

2.3 Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) during the installation of the GMVC96 furnace to ensure safety. This includes safety glasses or goggles to protect eyes from debris. Use insulated gloves to handle sharp edges or hot components. A dust mask is recommended when working with dusty materials. Steel-toe boots are essential to prevent foot injuries from heavy tools or equipment. Additionally, wear a hard hat if working in an area with overhead hazards. Proper attire, free from loose clothing, should be worn to avoid entanglement with machinery. Ensure all PPE fits correctly to provide effective protection during the installation process.

Pre-Installation Checks

Conduct essential pre-installation checks to ensure compatibility and compliance. Verify furnace specifications, prepare the site according to requirements, and check local building codes for compliance.

3.1 Verifying Furnace Specifications

Begin by verifying the GMVC96 furnace specifications to ensure compatibility with your system. Check the BTU rating, AFUE efficiency, and gas type (natural or propane). Confirm the furnace’s electrical requirements and venting configuration. Ensure the unit’s size matches your space and heating needs. Refer to the user manual for detailed specifications. Proper verification ensures safe and efficient operation, avoiding potential installation issues. This step is crucial for optimizing performance and warranty validity.

3.2 Site Preparation and Requirements

Ensure the installation site meets all requirements for the GMVC96 furnace. Choose a well-ventilated area, away from flammable materials, with adequate clearance for maintenance. The furnace must be installed on a level surface, securely fastened to prevent vibration. Ensure proper drainage and access for gas and electrical connections. Verify that the location complies with local building codes and manufacturer guidelines. Prepare the area by clearing any obstructions and ensuring the floor is level. Proper site preparation ensures safe and efficient installation, avoiding potential issues during operation.

3.3 Checking Local Building Codes

Before installing the GMVC96 furnace, it’s crucial to verify compliance with local building codes and regulations. These codes ensure that the installation meets safety standards and legal requirements. Check with local authorities to obtain necessary permits and inspections. Additionally, review the installation manual for any specific code-related instructions. Compliance prevents potential legal issues and ensures the furnace operates safely and efficiently. Non-compliance can lead to fines or system shutdowns, so thorough verification is essential. Always follow manufacturer guidelines that align with local regulations for optimal performance.

Tools and Materials Required

The installation requires tools like screwdrivers, wrenches, and a multimeter. Materials include venting components, gas line connections, and electrical wiring. Refer to the manual for specifics.

4.1 List of Necessary Tools

To install the GMVC96 furnace, you will need essential tools such as screwdrivers (Phillips and flathead), adjustable wrenches, pliers, and a multimeter for electrical connections. A gas leak detector is also required for safe installation. Additionally, a drill and bits may be needed for mounting the furnace. Ensure all tools are in good condition and suitable for the tasks involved. For venting, tubing cutters and a measuring tape are necessary. A level tool is also recommended to ensure proper alignment during installation. Always refer to the manual for specific tool requirements to avoid delays or safety hazards.

4.2 Required Materials for Installation

The installation of the GMVC96 furnace requires specific materials to ensure proper setup and functionality. These include venting pipes, elbows, and connectors for secure venting, as well as gas line components like flex lines, fittings, and a gas valve. Electrical materials such as wiring, connectors, and a circuit breaker are also necessary. Additionally, insulation and sealing materials like silicone sealant or tape may be needed to ensure airtight connections. A compatible thermostat and mounting hardware, such as screws and brackets, are essential for installation. Always verify compatibility with the furnace specifications to ensure safe and efficient operation.

Installation Process

The GMVC96 installation involves unpacking, inspecting, and positioning the furnace. Connect gas lines, electrical components, and venting systems, ensuring all connections are secure. Finalize by testing the furnace operation.

5.1 Unpacking and Inspection

Begin by carefully unpacking the GMVC96 furnace from its shipping crate. Inspect the unit for any visible damage or dents that may have occurred during transit. Verify that all components, including the furnace, venting kit, and installation hardware, are included. Check for any loose connections or misaligned parts. Ensure the furnace is placed on a level surface to prevent imbalance. Refer to the manual for specific unpacking instructions. This step is critical to ensure all components are in good condition before proceeding with the installation process. Proper inspection helps prevent potential issues during operation.

5.2 Mounting the Furnace

Mount the GMVC96 furnace on a level, sturdy surface to ensure proper operation. Use the provided hardware to secure the unit firmly in place. Ensure the furnace is positioned in a way that allows adequate clearance for maintenance and venting. Refer to the manual for specific mounting requirements, such as using wall brackets or a concrete pad. Double-check that the furnace is aligned correctly to maintain even weight distribution and prevent vibration; Proper mounting is essential for safety, efficiency, and to meet local building codes. Always follow the manufacturer’s guidelines for installation to avoid potential issues during operation.

5.3 Connecting Gas Lines

Connect the gas lines to the GMVC96 furnace according to the manufacturer’s specifications. Ensure the gas line is properly sized and compatible with the furnace’s requirements. Use approved materials, such as flexible gas tubing or rigid pipe, and secure all connections tightly. Turn off the gas supply before starting work and verify there are no leaks using a gas leak detector or soap solution. Follow local plumbing codes and safety guidelines to prevent hazards. Properly label the gas lines for future reference. Always test the system after installation to ensure safe and reliable operation. Refer to the manual for detailed instructions and diagrams.

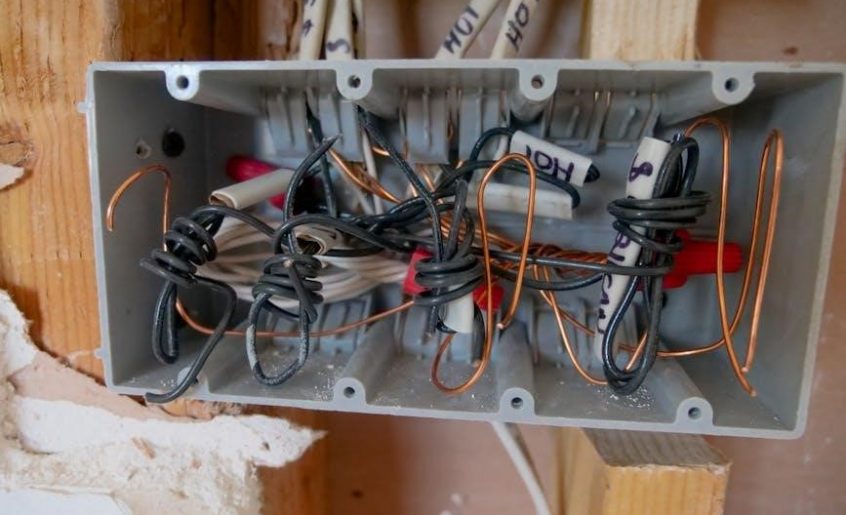

5.4 Electrical Connections

Connect the electrical components according to the GMVC96 furnace’s wiring diagram. Ensure the voltage matches the furnace’s specifications (typically 120V AC). Use appropriately sized wires and connectors to prevent overheating. Connect the thermostat wires to the furnace’s control board, ensuring proper polarity. Install a dedicated circuit breaker if required. Ground the furnace to meet safety standards and prevent electrical hazards. Double-check all connections for tightness and verify continuity. Refer to the manual for specific wiring requirements and safety precautions. Proper electrical connections are critical for safe and efficient furnace operation. Always turn off power before making adjustments or repairs.

5.5 Venting System Installation

Install the venting system according to the specifications in this manual. Use approved venting materials, such as PVC or ABS, and ensure proper sizing to match the furnace’s requirements. Route the venting system to avoid leaks or blockages, and seal all connections securely. Direct vent configurations are recommended for optimal performance. Non-direct vent setups may also be used if specified. Ensure the venting system complies with local building codes and safety standards. Proper installation prevents hazardous gas leaks and ensures efficient furnace operation. Refer to the manual for detailed venting diagrams and configurations. Always follow safety guidelines when handling venting materials and connections.

Startup and Testing

After installation, perform the initial startup checklist to ensure all systems function correctly. Test furnace operation, verify gas flow, and configure the thermostat settings for optimal performance.

6.1 Initial Startup Checklist

Before starting the furnace, ensure all electrical, gas, and venting connections are secure. Verify thermostat settings and power supply. Check for proper gas flow and venting. Test the furnace by raising the thermostat setting to activate heating. Observe burner ignition and operation. Ensure all safety features, such as limit switches, function correctly. Review the installation manual for specific startup procedures. Listen for unusual noises or odors, which may indicate issues. If everything operates smoothly, proceed to test the furnace under normal conditions to confirm reliability and performance. Always follow safety guidelines and manufacturer instructions during this process.

6.2 Testing Furnace Operation

After initial startup, test the furnace operation by simulating various heating demands. Verify proper ignition and flame consistency. Check the transition between heating stages to ensure smooth operation. Monitor the system for unusual noises or vibrations. Confirm that the thermostat accurately controls temperature settings. Test the emergency shut-off feature to ensure it functions correctly. Observe the venting system for proper airflow and no signs of blockage. Check for error codes on the control board and verify that all safety features, such as limit switches, activate as needed. If any issues arise, refer to the troubleshooting section or consult a professional for assistance. This step ensures the furnace operates safely and efficiently under normal conditions.

6.3 Configuring the Thermostat

Configure the thermostat to work seamlessly with your GMVC96 furnace. Ensure compatibility by selecting a thermostat designed for two-stage heating systems, such as the CTK02AA or ComfortNet-enabled models. Follow the thermostat’s installation manual to connect it properly to the furnace. Program the thermostat to optimize heating performance, setting preferences for temperature, humidity, and fan operation. Test the configuration by running through heating cycles to confirm smooth stage transitions. Verify that the thermostat communicates accurately with the furnace control board. If issues arise, consult the thermostat’s user guide or contact a professional for assistance. Proper configuration ensures efficient and precise temperature control.

Troubleshooting Common Issues

Identify and resolve common issues with your GMVC96 furnace by checking error codes, verifying thermostat settings, and ensuring proper gas supply. Refer to the manual for detailed diagnostics.

7.1 Identifying Error Codes

The GMVC96 furnace displays error codes to indicate specific issues. Common codes include LO, 9, and 13, which relate to ignition, gas valve, or sensor malfunctions. Refer to the manual for a full list of codes and their meanings. Ensure the furnace is powered off before troubleshooting. Check the display panel or consult the troubleshooting section for detailed explanations. If issues persist, contact a certified technician to avoid further complications. Always follow safety guidelines when diagnosing or repairing your furnace.

7.2 Diagnosing Common Problems

Common issues with the GMVC96 furnace include error codes, ignition problems, and sensor malfunctions. Start by checking the display panel for specific error codes, such as LO, 9, or 13, which indicate ignition or gas valve issues. Verify proper gas supply, ensure vents are clear, and check thermostat settings. Consult the troubleshooting section of the manual for detailed guidance. If issues persist, refer to the diagnostic charts or contact a certified technician. Always follow safety precautions when diagnosing or repairing your furnace to avoid further complications and ensure optimal performance.

7.3 Resetting the Furnace

To reset the GMVC96 furnace, first ensure the unit is powered off at the circuit breaker or switch. Locate the manual reset roll-out limit switches, typically small and round, near the blower or heat exchanger. Press and release these switches to reset them. If issues persist, check for error codes on the display panel, such as LO, 9, or 13, which indicate specific malfunctions. Refer to the troubleshooting section for code meanings. After addressing the root cause, restore power and test operation. Always ensure the furnace is cool and venting properly before resetting to avoid further complications.

Maintenance and Upkeep

Regular maintenance ensures optimal performance and prolongs the furnace’s lifespan. Clean the unit, inspect components, and schedule annual professional checks to maintain efficiency and warranty validity.

8.1 Cleaning the Furnace

Regular cleaning is essential for maintaining the GMVC96 furnace’s efficiency and safety. Turn off power before cleaning. Use a vacuum to gently remove dust from vents and internal components. Inspect and clean the filter according to the manufacturer’s instructions. Check the burner area for debris and ensure proper airflow. Clean the venting system to prevent blockages. Avoid using abrasive materials that could damage surfaces. Ensure the surrounding area is clear of flammable materials. For deep cleaning, consult the manual or contact a professional; Regular maintenance ensures optimal performance and prolongs the furnace’s lifespan while adhering to safety guidelines.

8;2 Inspecting Components

Regularly inspecting the GMVC96 furnace components ensures optimal performance and safety. Check the heat exchanger for cracks or corrosion, and verify the venting system for blockages or damage. Inspect the burner assembly for proper alignment and cleanliness. Ensure all electrical connections are secure and free from wear. Examine the gas lines for leaks and confirm proper pressure settings. Look for signs of wear on belts, pulleys, and motors. Address any issues promptly to prevent malfunctions. Refer to the manual for specific inspection procedures or consult a professional if unsure. Regular inspections help maintain efficiency and reliability while ensuring safe operation. Always follow safety guidelines during inspections.

8.3 Scheduling Regular Maintenance

Regular maintenance is essential for ensuring the GMVC96 furnace operates efficiently and safely. Schedule annual professional inspections before the heating season starts to identify potential issues early. Create a maintenance checklist that includes cleaning filters, inspecting vents, and checking gas lines for leaks. Ensure all components, such as the heat exchanger and burner, are in good condition. Maintenance not only prolongs the furnace’s lifespan but also optimizes its performance. Keep records of all maintenance activities for warranty purposes. Regular checks help prevent unexpected breakdowns and ensure the furnace runs reliably throughout the year.

Warranty Information

This manual outlines the warranty terms for the GMVC96 furnace, including the Lifetime Heat Exchanger Limited Warranty and 10-Year Parts Limited Warranty. Online registration is required within 60 days of installation, except in California and Québec. Proper installation and maintenance are essential to uphold warranty validity; Refer to the warranty section for detailed terms, conditions, and exclusions to ensure full coverage and protection for your investment.

9.1 Warranty Registration Process

To activate the GMVC96 furnace warranty, complete the online registration within 60 days of installation. Visit the manufacturer’s website, create an account, and provide installation details. Exceptions apply in California and Québec, where online registration is not required. Ensure all information is accurate to avoid delays. Print or save the confirmation for records. Proper registration ensures coverage under the Lifetime Heat Exchanger Limited Warranty and 10-Year Parts Limited Warranty. Failure to register may result in reduced warranty benefits. Refer to the manual or manufacturer’s website for specific instructions and requirements.

9.2 Terms and Conditions

The GMVC96 furnace warranty is subject to specific terms and conditions. Proper installation, as outlined in the manual, is mandatory for warranty validity. The furnace must be registered within 60 days of installation, except in California and Québec. Damage from improper use, lack of maintenance, or unauthorized modifications voids the warranty. Coverage includes parts and heat exchanger under specified conditions. Refer to the manual or manufacturer’s website for full details. Ensure compliance with all terms to maintain warranty benefits and protect your investment in the furnace.

9.3 Exclusions and Limitations

The GMVC96 furnace warranty excludes coverage for damage caused by improper installation, neglect, or unauthorized modifications. Normal wear and tear, corrosion, or damage from natural disasters are not covered. The warranty does not apply if the furnace is used outside its intended application or in non-residential settings. Claims must be submitted within the specified period, and proof of proper installation and registration is required. Certain parts, such as filters and ignitors, may have limited coverage. Review the full warranty terms for specific exclusions and limitations to understand your coverage boundaries and ensure compliance with all requirements.

By following this manual, you’ve successfully installed and configured your GMVC96 furnace. Ensure optimal performance by adhering to maintenance schedules and troubleshooting guidelines. Refer to the warranty information for any future service needs and enjoy efficient, reliable heating for years to come.

10.1 Final Installation Check

After completing the installation, conduct a thorough final check to ensure all components are functioning correctly. Verify gas lines for leaks, check venting for proper airflow, and confirm electrical connections are secure. Test the thermostat settings to ensure the furnace operates in both heating stages. Review the manual to confirm all safety features, such as limit switches, are operational. Ensure the unit is properly grounded and all filters are installed. Finally, confirm the furnace operates quietly and efficiently, with no unusual noises or odors. This final inspection ensures a safe and efficient heating system, ready for long-term use.

10.2 Ensuring Optimal Performance

To ensure the GMVC96 furnace operates at peak efficiency, regular maintenance is essential. Clean or replace air filters monthly and inspect heat exchangers annually. Check venting systems for blockages and ensure proper gas line connections. Configure the thermostat accurately to match the furnace’s two-stage heating capabilities. Monitor for error codes and address any issues promptly. Schedule annual professional inspections to identify potential problems early. Keep the surrounding area clear of debris to maintain airflow. By following these steps, you can maximize energy efficiency, reduce operational noise, and extend the furnace’s lifespan, ensuring reliable heating performance for years to come. Proper maintenance also helps prevent unexpected breakdowns and enhances safety.